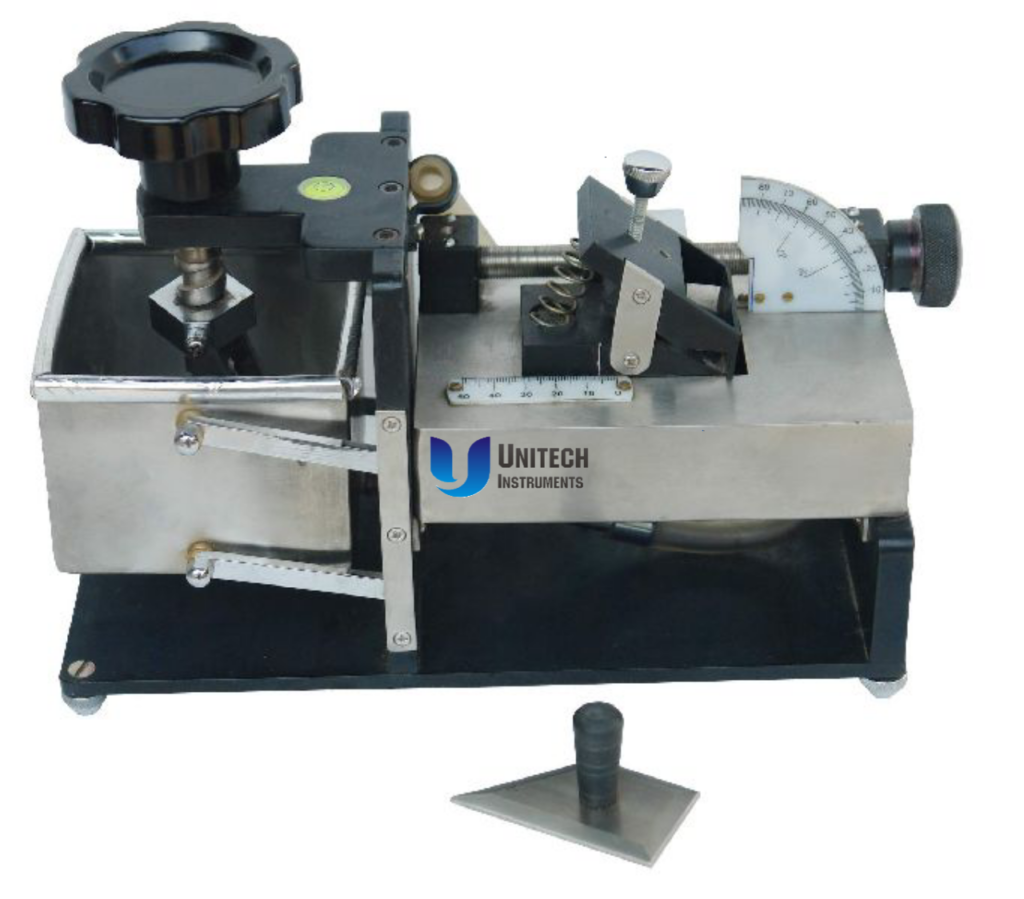

COBB TESTER

DISCRIPTION

For determining the water absorbency of paper, paperboard and similar material. The water absorbency of paper (the Cobb value) is defined as the quantity of water absorbed in a given time by one side of a unit area of paper or board placed horizontally under a head of one centimetre of water

Convenient spring loaded sample clamping system presses the cylinder against the sample on the rubber mat so that a leak proof seal is obtained. The clamping force is adjustable. The cylinder lifts when 2 handle bars are pinched together

Easy and safe clamping mechanism. The clamping system presses the cylinder against the sample on the rubber mat so that a leak proof seal is obtained and can be tilted with a knob to contact with water.

SPECIFICATIONS

The container mounted on a stand and filled with the specified quantity of water, The Pre-weighted sample clamps and get in contact with water, After the test time has elapsed, it is turned back and this surplus water is removed by pressing the test piece between standard blotter under a steel roller supplied along with equipment. The weight increase with the exposure of water is called cobb value

It also gives indications of the additive substances applied during process that improve printing quality and resistance to liquids.

Test area: 100 cm

Level indication: Indication for 100 ml on the inside of the cylinder

Couch roll: Stainless Steel roller having a smooth surface Width 210 mm (8”) Diameter 88 mm (3.6”) Weight 10 Kg. +- 0.5 Kg.

Option:

Stop watch, Graduated cylinder 100 ml

Digital weighing Balance .001 gram

Standard blotter GSM 200 and capillary 60 mm

PAPER CURL TESTER

This instrument is used to evaluate the Degree of curl when the paper sample exposed to water.

This method applies the principle of wetting one side of the paper and determining the maximum curvature developed or the time required to reach maximum curvature .

The maximum Curvature is an indication of relative tendency of certain paper, especially, to curl under normal condition of usage. The time required to reach maximum. Curvature is measure of relative degree of sizing such as secured with rosin (3)

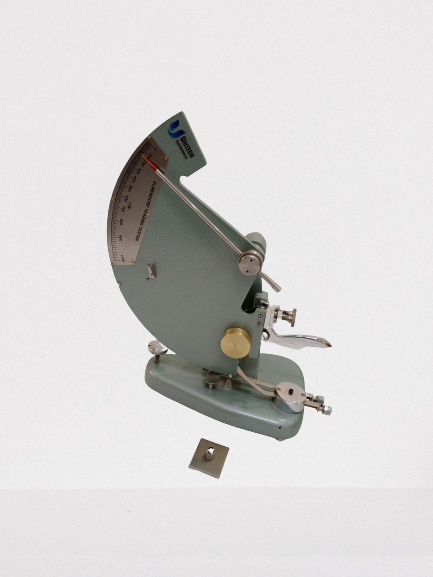

TEAR TESTER

DISCRIPTION

This instrument is used for measuring the Resistance against Tearing of Paper, Board, Plastic Films and other similar materials. The Pendulum which is free to swing on its horizontal axis with a calibrated scale mounted on it, which indicates the Mean Tearing Force. The main Unit is provided with single pendulum.

Extra on Demand:

“Tearing Sample Cutter”

“Set of Calibration Check Weights”

“Interchangeable Pendulum for different range”

1.Extra Light-A/4 (0-2000 m N)

2.Light-A (0-8000 m N)

3.Medium-B (0-16000 m N)

4.Heavy-C(0-32000 m N)

5.Extra Heavy-D (0-64000 m N).

Applicable Standards : SCAN P 11, TAPPI T414, CPPA D.9, ISO 1974, BS 4468, DIN 53128, APPITA/AS 1301.400

PULP DISINTEGRATOR

Description

This instrument is used for standardized disintegration of pulp to a homogeneous suspension required for preparation of laboratory hand sheet and other purpose. Pivoted drive unit with stainless steel propeller and shaft. The propeller is driven by electric motor via stepped timing belt, which ensures a direct drive without slippage.

Extra Option:

- Mechanical Preset impulse Counter on front panel for setting desired number of revolution.

- Digital Preset Pulse Counter on front panel for setting desired number of revolution.

- SS Pulp Container 2Ltr with Heating Elements.and Thermostat control.

SPECIFICATIONS

| Construction | : Made of stainless steel container an and aluminimum fabricated body |

| Capacity | : 2 Litres with for equally spaced spiral baffles. |

| Propeller | : The three blade propeller mounted on a vertical shaft as per standard radius. |

| Cabinet Type | : Hinged top for quick opening. |

| Rotational Frequency | : 2975 ± 25 rpm. |

| Motor | : 0.5 KW, 3 Phase, 440V AC |

| Safety System | : Double Safety System permits start only when drive unit and vessel are in correct working position. |

| Applicable Standards | ISO 5263, TAPPI 205/220 SCAN C18/M2, CPPA C6 |

OPTION:

1. Preset Pulse Counter on front panel for setting desired number of revolution.

2. Pulp Container with Heating Elements, Thermostat and 100% safe insulation.

The thermostat control is set at 85 Oc to maintain constant temperature of stock

Changes:

Unitech Instruments looking Forward to develop Products. The technical data in this catalogue are therefore subject to change..

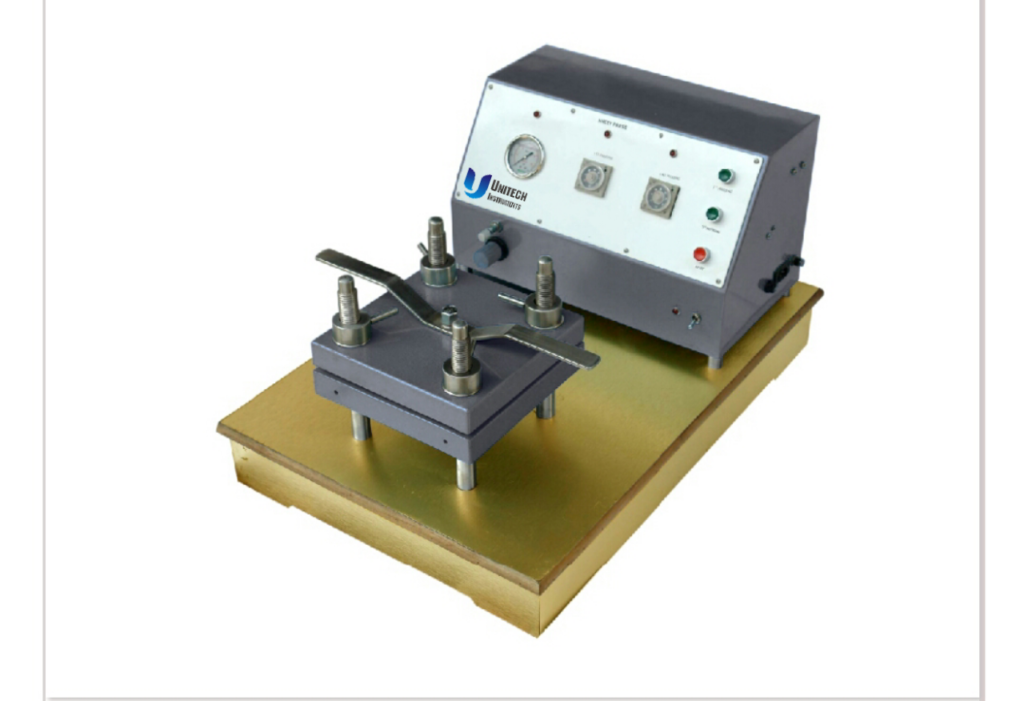

BURSTING STRENGTH TESTER

DISCRIPTION

This is the optimum equipment for determining the bursting strength of paperboard, corrugated board or solid fiberboard material. The specimen is tightened by screw clamping through rotation of wheel handle. The bursting pressure, at the time of rupture is recorded on a sensitive pressure gauge which indicates the test results in Kg /Cm² or in PSI units. Measuring Range – 0 to 50 Kg./cm².

Accessories on Demand:

- Double Pressure Gauge Assembly for fitting of Extra Bourdon Pressure Gauge.

- Standard Reference Testing Foils.

- Standard Pressure Gauges with Set Point Indicator, Range 0 – 10/14/21/42/70 Kg/cm².

- Glycerol Fluid.

- Rubber Membrane Diaphragms.

STIFFNESS TESTER

The Unitech Instruments Stiffness Tester is designed to evaluate stiffness and resiliency properties of materials up to 10,000 Taber Stiffness Units (g cm). This precision instrument provides accurate test measurement to ±1.0% for specimens 0.004″ to 0.219″ thickness at angles 7 1/2° or 15°.The testing Materials include Paper Products, Cardboard, Plastics, Metallic Sheets and other flexible material.

Extra on Demand:

“Triple Shear Cutter for Sample Preparation”

“Calibration Standard strips”

| Product Code | UI-1001 |

| Equipment Category | Paper Testing Equipments |

| Weight | Stiffness Unit – 6.350 Kg., Accessory -Triple shear cutter- 2.0 Kg. |

| Dimension | Stiffness Unit – 24.0 x 28.0 x 41.5 cm., Accessory -Triple shear cutter- 24.0 x 12.5 x 8.5 cm. |

| Applicable Standards | TAPPI 489 m-69, ASTM D-747-61-T, JIS P-8185 |

| Range Available |

CONCORA MEDIUM FLOTTER (HORIZONTAL TYPE)

The UEC “Concora Medium Fluter” is widely used for preparation of the corrugated samples to evaluate the CMT and CCT tests. The temperature of the “Fluting Rolls” is maintained at a constant 176°C through the Digital Temperature Indicator Cum Controller (PID) for uniform sample preparation.

The standard model is provided with ‘A’ flute and “Rack & Comb” set.

Optional on Demand:

Flute “A” / “B”/“C”.

“CCT (Corrugated Crush Test) Sample Holder”

“Precision Sample Cutter – Sample Size 0.5 x 6”

DETAILS:

PRODUCT CATAGORY : PHYSICAL PROPERTY TESTING INSTRUMENTS

APPLICABLE STANDARD : DIN EN ISO 7263, TAPPI T809, SCAN P 27, PAPTAC D 29, APPITA/AS 1301.434s

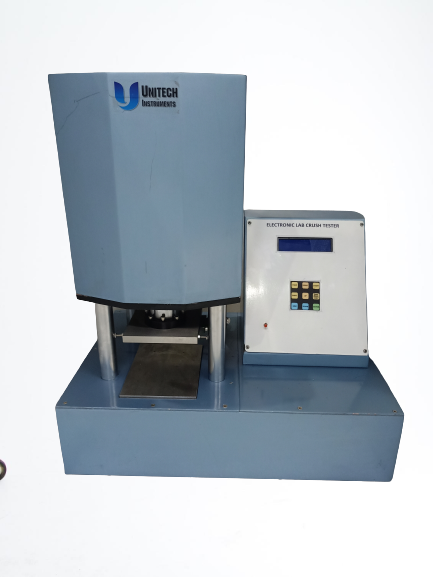

RING CRUSH TESTER

The Unitech Instruments Ring Crush Tester is used for accurate testing of Paper, Paperboard, Solid Fiberboard & Corrugated Board for RCT, ECT, CCT, FCT, PAT & CMT Test, as well as Performing Compression Test on Small Packages (Mono Cartons).The unit is provided with standard Load range 0-500 Kg f (5000 N).

The RCT “Test Sample Holder” & “Removable Disc” (08 numbers) for the sample thickness of 0.15 mm to 0.49 mm are supplied with the main unit.

Optional Facilities on Demand:

“Inbuilt Thermal Printer” to take the Printout of Test Data.

“Software” to transfer the test data to PC through RS 232 communication port

Optional Test Accessories on Demand

For RCT: Sample Test Strip Cutter.

For ECT: Sample Cutter, Circular Neck Down Cutter & Sample Holder.

For FCT: Sample Circular Cutter ( To measure the Resistance of Flutes )

For CCT: Sample Holder.

For PAT: Sample Holder for Corrugated Board.

For CMT: The CMT test measures the Crushing Resistance of a Lab Fluted Strip of Corrugating Medium.

Concora Medium Flutter : for Preparation of Corrugated Samples for CMT & CCT Tests.

PRODUCT DETAILS :-

EQUIPMENT CATAGORY : Physical Property Testing Instruments

WEIGHT : 61.700 Kg (Approx.)

DIMENTION : 54.5 x 37.5 x 64.0 cm.

APPLICABLE STANDARDS : APPITA/AS 1301.449, FEFCO No.50

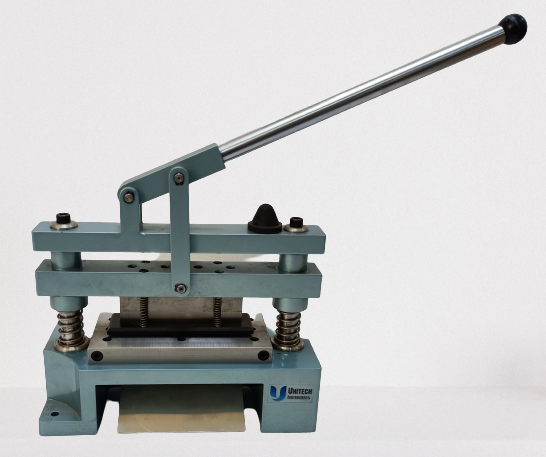

PUNCH & DIE CUTTER

The Unitech Instrument Precision Test Strip Punch & Die Cutters are intended for accurate and rapid preparation of test pieces for use in Ring Crush Test, Folding Endurance Schopper, Ply Bond Test and other similar tests without any deformation and damage. It is suitable for cutting Test Samples from paper and paperboard.

PUNCH & DIE CUTTERS AVAILABLE ON DEMAND :

1.For Ring Crush Test (RCT) – Cut size: 12.7 x 152.4 mm.(1/2″ x 6.0″)

2.For Folding Endurance (SCHOPPER Type) Test – Cut size: 15 x 100 mm.

3.For Ply Bond Test – Cut size: 25.4 x 152.4 mm.(1.0″ x 6.0″)

4.For Short Span Test ( SCT) – Cut size: 15 x 150 mm.

DETAILS

EQUIPMENT CATAGORY : PHYSICAL TESTING INSTRUMENTS

WEIGHT : 25.00 kg (Approx.)

DIMENSION : 75.0 X 38.0 X 43.5 cm.

APPLICABLE STANDARD : ISO 3035, 7263, 3037, 536, 1924, TAPPI T 822, T 809, T 410, T 494

DIGITAL THICKNESS MICROMETER

THICKNESS MICROMETER

The thickness of sheet is measured as the distance between two circular plate surface, under a steady pressure 1Kg/cm² (98.0 kpa) For rapid and accurate measurement of thickness paper, board and pastic, motorized sturdy easy to use and “PUSH THE BOTTON” operation. Digital display, Mitutoyo Japan make add-on-type optical transducer.

Rapid Sheet Dryer

Description

This instrument is used for shortening the drying time of wet pulp or paper samples before determining the dry weight or moisture content. It is provided with flat heating elements. Stainless steel sheet fabrications with insulating material ensure long service life.

Suitable for Sheet Size:

Max. width 250 mm, Max length 300 mm.

Temperature adjustable over a wide range upto maximum of 180o ± 10oC.

SPECIFICATIONS

Rectangular Drying Plates.

Lower plate is lined with wire cloth to lead off the vapour during the drying process.

Provided with overheating protector.

Switch provided with indicator lamp.

Upper and lower drying plates are heated with flat electrical elements.

| Sheet Size | : Max. width 250 mm Max length 300 mm |

| Temperature range | : Adjustable over a wide range, upto maximum of 180 oC ± 10 oC. |

| Heaters | : Flat Electrical Elements single phase, 220 V, 400 W each for upper and lower plates |

| Power Supply / Consumption | : 220 V, Single Phase, 50 Hz. / 800 W |

| Applicable Standard | : SCAN M- 1 |

Changes:

Unitech Instruments looking forward to develop Product. The technical data in this catalogue are therefore subject to change.

A Laboratory Sheet Press (Pneumatic Type)

This instrument is used for pressing and de-watering the sheet quickly made on sheet making machine. Hydraulic Type Manually Operated and plunger type pump is employed for raising the pressure gradually.

Working pressure 3.5 kg / cm 2 ,

Standard Model sheet size dia 165 mm.

Suitable for other size: 160/165/200 mm diameter.

DISCRIPTION

This Pneumatically Operated Sheet Press is used for quick Pressing and de-watering of the sheets in a uniform manner, in accordance with “Industry Standards”. The sheet press consists of press section and control panel . The press platens are made of stainless steel with, the bottom one adjustable to allow for the loading of varying numbers of hand sheets, pressing time & pressure can be preset to conform with the Industry Standards and the “Pressing Cycle are Automatic”. The control panel consists of pre-determining timers for two pressing cycles.

The working pressure is 3.5 kg / cm² and the standard press platen size is 330 x 350 mm.

| Applicable Standards | SCAN C 26 : 76, M 5:76, TAPPI T205 OM88, CPPA C.4, ISO 5269/1 |

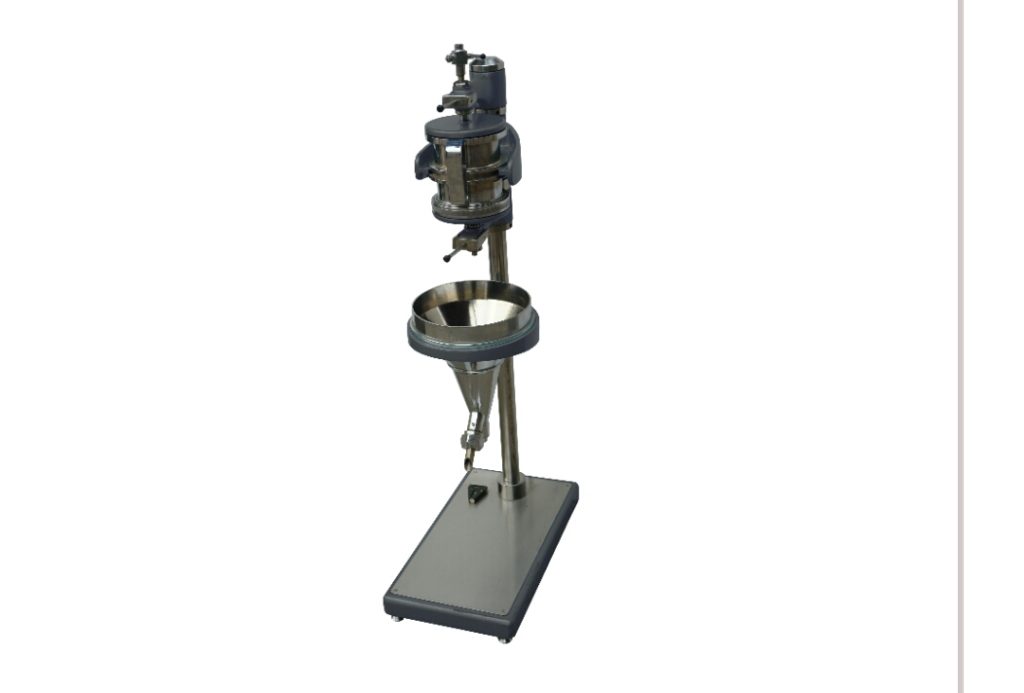

Description

This instrument is used for determination of freeness of wood fibre ground wood and mechanical pulp. It measures the Canadian Freeness numberwhich is a measurement of the drainage capacity of different pulp types.

It is a useful index of the amount of mechanical treatment given to the pulp With standard screen plate and Plexiglas measuring cylinder for CSF value.

3 grams of OD fibre pulp in aqueous suspension is drained through the fibre mat on a standard perforated screen plate during the test into a funnel provided with a bottom and side orifice.

The filtrate collected in specially graduated measuring cylinder from the side orifice is expressed as a CSF value corresponds to milliliter.

SPECIFICATIONS

Its Nozzle and screen plate are calibrated according to relevant standards. Two measuring cylinders are included.

| Capacity of the cylinder | : 1000 ml above the screen plate |

| The Volume in the Bottom section of the cone | : 23.5 ± 0.2ml (adjusted by means of the threaded plug in the side orifice) Any change in this volume may affect the calibration. |

| Slope of the main cone | : 29o ± 5 min. |

| Orifices provided in funnel | : Two, one at the bottom & other on the side. |

| Distance between the overflow lip of the tube (inside the funnel) and bottom of the funnel section | : 50.8 mm ± 0.75 mm Note: This is extremely critical and set precisely at the works. |

| Size of the perforations in the | : 0.51±.01 mm diameter and no of holes are 97 per/cm2 screen plate (TAPPI STANDARD) |

| Compliance to the following International Standards | : ISO 5267/2 CPPA C1 BS 6035/2 TAPPI T 227 |

Option

Spare screen plate

Wall mounted model.

Consistency determination appratus

Changes:

Unitech Instrument looking forward to develop Product.The technical data in this catalogue are therefore subject to change.

Lab Bar Coater

Designed for the application of the paints, varnishes, adhesives, liquid printing inks starch and many other surface coating using wire wounded metallic bar under accurately controlled conditions with variable coating speed between 2 and 15 mm/min which provides uniform coating.

- The Equipment consists of 7 Nos coating rods which provide different coating thickness.

- The coated area is 27 cm x 15 cm (Standard)

FLOATATION CELL

Description

This instrument is used to study the de-inking effect of printed recycled paper by floatation method in laboratory. Stainless steel container capacity 25-liter specially designed aerator with variable speed and digital revolution counter. Can be used in conjunction with laboratory Pulper and screw press to conduct extensive testing of recycled fiber system.

Extra Optional :

High-consistency pulper

SPECIFICATIONS

To study the dinking effect of printed recycled paper by floatation method in laboratory. Stainless steel container capacity 25-liter specially designed aerator with variable speed and digital revolution counter. Can be used in conjunction with laboratory Pulper and screw press to conduct extensive testing of recycled fiber system. Lamort type original kowaleswski flotation cell method.

| Containor Capacity | : 25 Liter Stainless steel containor with outlet valve . |

| Revolutation Counter | : 6 Digit digital revolation counter. |

| Power Supply | : 220 V, Single phase, 50 Hz. 200 W |

Option:

Above model with digital temperature indicator controller and online PH indicator

High Consistency Pulper use as a third chemical formulation for fine despertion of the ink partical.

| Shipping Data |

Changes:

Unitech Instruments looking forward to develop Product. The technical data in this catalogue are therefore subject to change

HYDRA PULPER

Description

This instrument is used for making pulp, minerals fibers pulp like mica, asbestos etc. Also used for mechno-chemical pulping. Heating System with adjustable Thermostat Control. Supplied with standard Electric motor, propeller V belt drive to circulate the stock effectively

- 10 Litre Capacity

- 30 Litre Capacity

- 50 Litre Capacity

- 100 Litre Capacity

Extra Optional :

Digital Temperature indicator cum controller With AC variable drive & digital temperature indicator cum controller.

INTERNAL PLYBOND TESTER

DISCRIPTION

It is designed for determining the Internal Bonding Strength of Paper, Paperboard and Laminates, by measuring the Average Energy, in Thousandths of foot Pound required to “Delaminate the Sheet Type Specimen” in two piles.The Internal Ply Bond Tester has found many other uses in quality control laboratories in paper industry. The unit is used to measure the average force, in thousandths of ft. lb., required to de-laminate the fibers in the paper specimen, as described by the TAPPI “USEFUL METHODS 403”

TECHNICAL DETAILS

The unit consists of “Dual Capacity Pendulum” of range 0-0.25 Ft./ lbs. & 0.1-0.5 Ft./ lbs. with test result, directly readout on the calibrated scale. The Five Number Specimen Preparation Unit with different Clamping Pressures from 50 to 200 PSI.

Optional On Demand:

1. Sample Preparation Strip Cutter Die & punch Type for Sample Strip Size – 25.4 x 152.4 mm (1.0″ x 6.0″).

2. Double sided adhesive tape of width 1” for Sample Preparation.

3. Standard Calibration Sliding Weights & its Holder.

Wood Chip Classifier

Description

For rapid, reproducible and accurate classification of wood chips in respect to size and thickness by using standard size screening trays mounted on a shaking mechanism with specified frequency.

A weighted quantity of the sample put in the upper screening tray with chips and fractionated through different diameters and slot screens. The structure is shaken in horizontal plain with specified frequency. The fractionated chips collected from each screen are weighted and the contents from each screen can be calculated in percentage.

SPECIFICATIONS

| Sample size | : 8 – 10 litres. |

| Recommended dry content | : 40 – 70%. |

| Screening time | : 10 minutes (Wet chips samples to be dried for 1-2 hrs before screening) |

| Screening trays | : Made of aluminium, (Shaken in horizontal plane by means of an eccentric gear) |

| Shaking frequency | : 2.7 Hz. |

| Stroke | : Stroke 120 mm. |

Recommended Standard Screen: (From Top)

No. 1 With 45 mm Dia Hole and triangular pitch 60 mm.

No. 2 With 8 mm wide slots

No. 3 With 7 mm dia holes and triangular pitch 8.5 mm

No. 4 With 3 mm dia holes and triangular pitch 8 mm

No. 5 Dust Pan

Rugged Steel stand with guard rail.

i. Other size hole diameters and slot width.

ii. Other power supplies.

Ref. Stanard: TAPPI UM 21, SCAN CM 40

HOLLANDER BEATER

DISCRIPTION

The Hollander Beater is used for uniform treatment of cooked / uncooked raw material under standard conditions for producing the pulp as per commercial production of Hand Made sheets. The motorized unit provided with Tub, Bed Plate, Rotor & Cover and Drain Valve i.e. complete in all manners and is mounted on the sturdy base frame.

Regular Model: Pulp Capacity -1 Kg

Customized Models: Capacity 2 kg. / 3 Kg. / 4 Kg. are manufactured.

Models with full stainless steel 316 Tub are also available.

Must Accessory for Pulp Washing: Motorized Washing Drum with fitting assembly.

Power Connection Required – 3 Phase.

VIBERATING SCREEN (Johnson Type)

Description

This instrument is used for separating shieves and fiber flock from a continuously fed pulp sample. Design approved by the Technical section of the British Paper & Board Industry Federation.

Average capacity: 5 Kg dried pulp per hour.

Strainer area 500 X 240mm.

Screen Slot width 0.20 mm standard

Extra Optional :

i. Other slot width as per customer requirement.

SPECIFICATIONS

Strainer plate and collecting tray are made of non corrosive material.

Average capacity equivalent to 5 kg. dried pulp per hour.

Strainer Area 500 X 240 mm.

Standard Strainer plate has 0.15 ± 0.1 mm slit width.

Ecentric drive by cam which accaute spring loaded frame.

The water spraying provide by Nozzelescontinously to the screen during operation.

The shive and coarse fiber vibrates and seperates through hoppers and fine pulp pass through the slots and discharge via side outlet.

Motor Drive 0.5 HP 1440 rpm.

OPTION

Other slots width 0.20, 0.30, 0.40 & 0.50.

Different holes size.

Higher capacity model.

Changes:

Unitech Instruments looking forward to develop Product. The technical data in this catalogue are therefore subject to change.

SHEET FORMER

DISCRIPTION

Sheet Former is a traditional system to place on a countertop through manual agitation.The filling is carried out through the water pressure network through its inlet and the emptying by gravity. 159 mm diameter sheets are obtained. The equipment is made of stainless steel. Possibility of manufacturing a model to make square sheets. For this sheet forming system, a sheet press and a quick dryer are necessary. The equipment comes with a set of discs for pressing and a set of rings for air drying.

ACCESSORIES

Manufactured in stainless steel. Diameter of the leaves of 159 mm. For placement on a countertop. Simple and precise in the manufacture of the sheets. Includes agitator and roller. Drying discs, drying rings and blotting paper.